- Material

-

- Aluminium 61

- Brass 8

- Stainless Steel 8

- Galvanised Steel 1

- Mild Steel 1

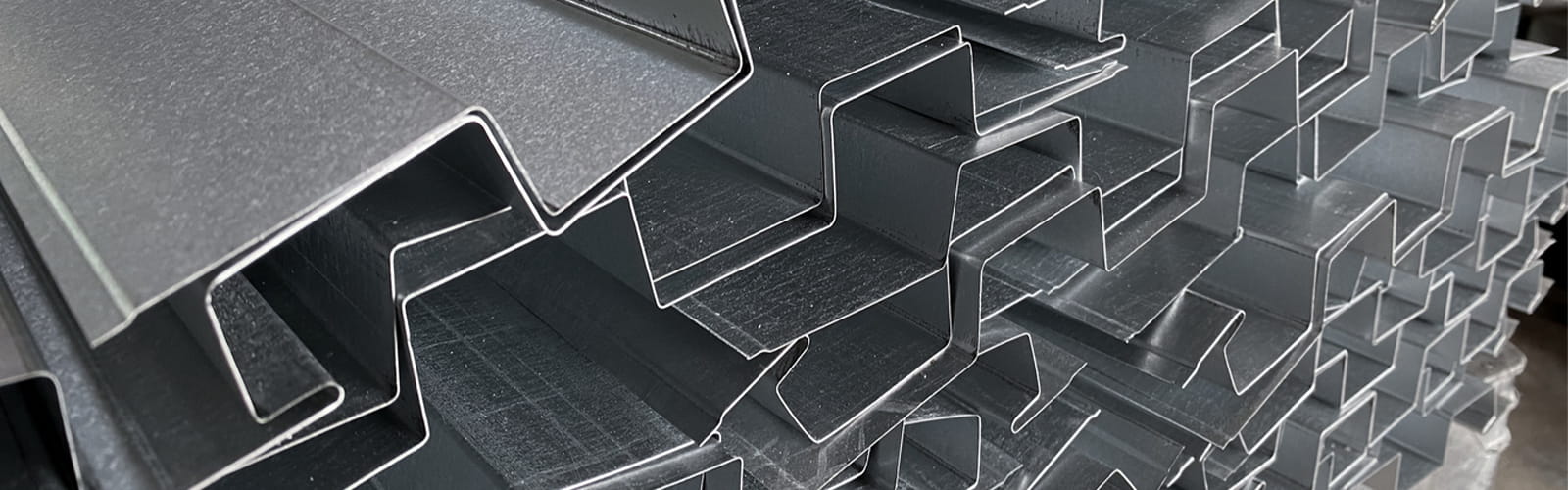

Why Is Galvanised Steel in Construction So Widely Used?

Galvanised steel in construction is widely specified because it protects steel from corrosion, supports long service life, and delivers consistent performance in line with UK building standards. By coating steel with zinc, galvanisation reduces the impact of moisture, weather, and environmental exposure that can weaken unprotected steel over time.

On-site, steel often appears okay during the installation, only to degrade years later. Exposed fixings can corrode, external supports deteriorate, and maintenance demands increase. These outcomes are frequently linked to material choices that did not fully account for long-term exposure conditions. Galvanised steel addresses this risk early, helping structures retain strength and reliability while limiting avoidable maintenance.

This article explains how galvanised steel works, why it is trusted across UK construction, and what professionals should consider when specifying it for durable, compliant builds.

How Galvanised Steel Protects Structural Steel From Corrosion

Galvanised steel is carbon steel coated with zinc to slow and control corrosion in structural and exposed applications. In construction, this is most commonly achieved through hot-dip galvanising, where fabricated steel components are immersed in molten zinc to create a continuous, bonded protective layer across surfaces, edges, and fixings.

This zinc coating protects steel through barrier and sacrificial action. It limits contact with moisture and oxygen and corrodes in preference to the underlying steel if the surface is damaged. This is particularly relevant on construction sites, where cut edges, fixings, and minor abrasions are difficult to avoid during installation.

UK safety and infrastructure guidance highlights corrosion as a critical material risk. The Health and Safety Executive (HSE) identifies corrosion as the single largest cause of plant and equipment breakdown, with external atmospheric corrosion presenting a greater risk than internal corrosion in many environments [1]. This reinforces the importance of selecting protective systems at the design stage, especially for steel used outdoors or in damp conditions.

For projects requiring predictable service life, galvanised steel provides a widely adopted method of managing corrosion risk without reliance on frequent maintenance.

What Professionals Consider When Specifying Galvanised Steel

When galvanised steel is specified in construction, decisions are typically driven by long-term risk and project constraints rather than material preference alone. Designers and contractors must balance exposure conditions, access limitations, and the implications of corrosion-related failure over time.

Key specification considerations include:

- Exposure conditions and location. External steelwork, ground-level components, and partially enclosed structures face a higher risk of atmospheric corrosion, which influences coating selection early in the design process.

- Access for inspection and intervention. Steel elements that are difficult to reach after installation benefit from protective systems that perform without regular inspection or remedial work.

- Design life and performance expectations. Galvanising supports predictable performance across the intended lifespan of a structure, particularly where safety-critical elements are involved.

UK industry guidance continues to recognise galvanising as an effective corrosion-control approach, with durability and exposure conditions central considerations. The British Galvanizers Association outlines why galvanised coatings are widely used for steelwork in construction and external environments [2].

Where Galvanised Steel Is Most Commonly Used on Site

Galvanised steel is commonly used in construction applications where exposure, access constraints, and long-term performance must be managed from the outset. It is specified across both structural and safety-related elements.

Typical on-site uses include:

- Structural frameworks, beams, and supports. Galvanised finishes help protect load-bearing elements in external or semi-exposed locations where ongoing maintenance may be impractical.

- Guardrails, balustrades, and access features. Zinc coatings support surface integrity in high-traffic and safety-critical areas over extended service periods.

- Roofing sheets and external cladding. Protection from rain and condensation helps extend service life without the need for frequent recoating.

Because galvanised steel performs consistently across varied site conditions, it is well-suited to renovation, fabrication, and custom projects that require long-term reliability.

Meeting UK Building Standards & Structural Steel Requirements

Compliance is a key reason galvanised steel in construction is specified on regulated projects. In the UK, hot-dip galvanising is commonly carried out to BS EN ISO 1461, which sets requirements for coating thickness, finish, and corrosion protection so specifiers can assess quality consistently.

Standards-based specification supports practical outcomes on site. It helps with traceability, inspection planning, and long-term performance decisions, particularly where steel is exposed or safety-critical. When galvanising forms part of fabricated structural steelwork, it must also align with wider construction product obligations.

Guidance from the European General Galvanizers Association explains how galvanising to EN ISO 1461 supports CE marking under EN 1090, including how durability is referenced within the Declaration of Performance [3]. The guidance also confirms that CE marking for construction products became mandatory from 1 July 2013, with fabricated structural steelwork covered from 1 July 2014.

We Make Galvanised Steel Easy to Specify & Source

Specifying galvanised steel in construction requires more than selecting a corrosion-resistant material. It involves coordinating exposure conditions, fabrication requirements, lead times, and delivery so that steel arrives ready to install and perform as intended.

Click Metal supports this process by supplying galvanised steel cut to exact measurements, helping improve on-site accuracy and reduce unnecessary waste. With over 70 years of experience within the metals industry, our team combines practical knowledge with a straightforward online ordering process, making it easier to compare materials and select the right option for each application. Additional support is available through our metal processing services, with clear delivery information to support project planning.

If your project requires materials or volumes beyond our standard range, additional options are available through Click Metal’s parent company, Doré Metals. This allows access to a wider selection of products and specialist support for more complex or large-scale requirements. For further information, you can explore additional options or contact the team directly at [email protected].

Call 01794 526090 or enquire now to discuss your galvanised steel requirements and arrange a supply that fits your project programme with confidence.

External Sources

[1] The Health and Safety Executive (HSE), “corrosion as the single largest cause of plant and equipment breakdown”: https://www.hse.gov.uk/comah/sragtech/techmeasmaterial.htm

[2] The British Galvanizers Association, “galvanised coatings are widely used for steelwork in construction and external environments”: https://galvanizing.org.uk/corrosion/corrosion-protection/

[3] European General Galvanizers Association, “galvanising to EN ISO 1461 supports CE marking under EN 1090”: https://www.galvanizingeurope.org/wp-content/uploads/2014/07/EGGA_CE_JUNE2014.pdf