- Material

-

- Aluminium 61

- Brass 8

- Stainless Steel 8

- Galvanised Steel 1

- Mild Steel 1

How to Start Metal Shaping at Home

Every maker or hobbyist remembers shaping their first piece of metal. There is something untouchable about the moment a flat sheet becomes something functional. Learning metal shaping at home is a hands-on way to see how materials react to pressure. It also helps you build accuracy and control through practice.

To put it bluntly, metal shaping is the process of bending, folding, and hammering metal sheets into various shapes. It helps achieve both structural and decorative effects. This remains a core skill across engineering, construction, and product design. According to the Health and Safety Executive (HSE), using correct shaping and handling techniques improves material integrity and reduces the likelihood of defects in fabricated parts. Aluminium is an ideal starting material as it is lightweight, resistant to corrosion, and easy to shape. This makes it safe for beginners to get clean results.

This guide covers essential shaping methods and best practices for accuracy and safety in the workshop.

Set Up for Success & Prepare Your Space

Practical metal shaping starts with preparation and a safe workspace. We mentioned in the introduction that aluminium is ideal for beginners due to its light weight, flexibility, and low density. Yet, the Confederation of British Metalforming also reports that this material plays a key role in UK manufacturing. They note that metal forming serves high-profile sectors, including aerospace, automotive, and construction.

Before starting, ensure your space supports safe, controlled work:

- Set up a stable, well-lit bench or vice to reduce vibration.

- Maintain ventilation and keep the workspace clean for optimal visibility and comfort.

- Wear protective gear, such as gloves, goggles, and ear protection, in line with HSE workshop safety guidelines.

Preparation and consistency reduce errors during bending or folding. For trade or DIY users, our metal categories offer precision-cut materials. So you can begin your projects safely without the need for trimming or machining.

3 Core Metal Shaping Techniques for Beginners

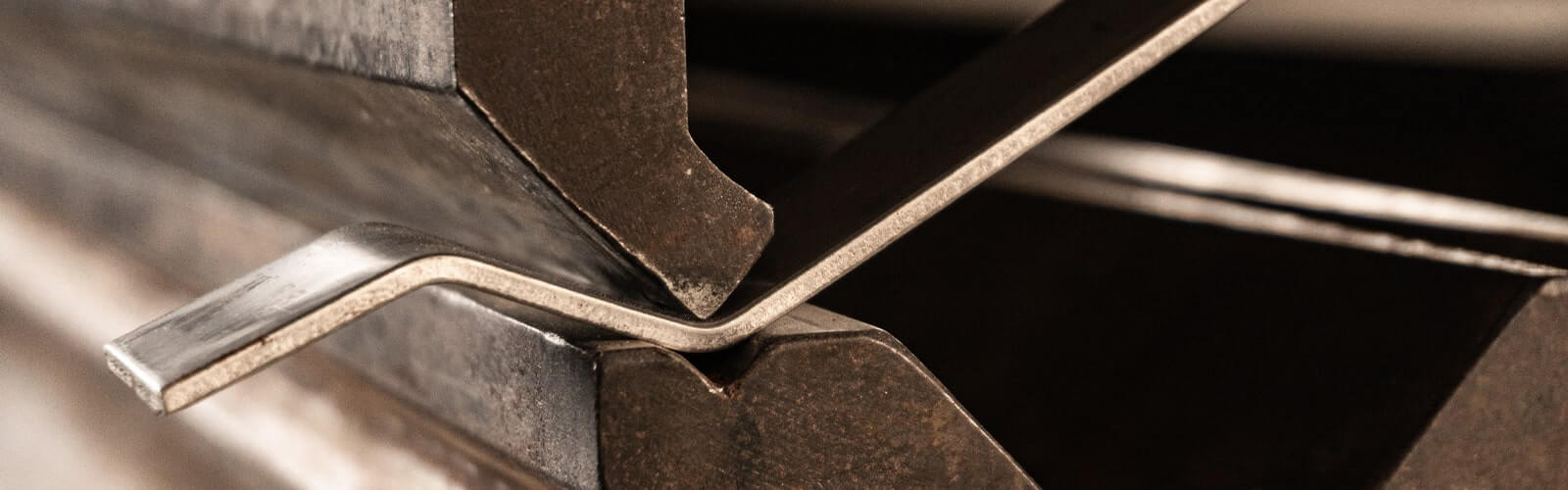

There are three key methods in metal shaping: bending, folding, and hammering. Each requires steady pressure and control to create smooth results without harming the surface.

Bending Metal

Bending creates curved or angled forms without cutting the sheet. Industry standards recommend applying controlled, gradual pressure while bending to prevent material failure. This approach also maintains high structural quality during the forming process.

To bend metal accurately:

- Secure the sheet or bar in a vice.

- Apply steady pressure along the bend line with a lever or bar.

- Avoid sharp movements to prevent cracking.

Aluminium and mild steel are flexible enough for moderate bends in panels, brackets, or frames. WorldSkills UK asserts that metal fabrication is a vital component of the UK engineering industry. It encapsulates skills used in construction machinery, structural steel, and aircraft manufacturing. Therefore, it is not as niche as you might be thinking.

Folding Metal

Folding forms sharp, defined edges, typically at angles of up to 90 degrees. Use a folding brake or straight edge for clean results, applying pressure evenly to prevent distortion. Aluminium’s flexibility allows it to hold shape with minimal rebound.

For precise folds, use our metal processing services. We provide pre-cut and machined aluminium plates ready for fabrication.

Hammering Metal

Hammering shapes metal through controlled strikes, making it ideal for curves or textured finishes. Use a rubber or wooden mallet and work gradually over a sandbag or block for smooth results. HSE guidance on workshop safety recommends using the correct technique and applying controlled force with hand tools. This helps reduce worker fatigue and prevents damage to materials.

Step-by-Step Guide to Shaping Aluminium Plates

Aluminium is an excellent material for metal shaping. Its strength-to-weight ratio and resistance to corrosion make it very practical. The Aluminium Federation (ALFED) notes that its formability and low density make it ideal for small-scale fabrication and prototyping.

Follow these steps for consistent shaping:

- Measure and mark precise lines using a steel ruler and scribe.

- Secure the plate firmly in a vice or on a flat surface.

- Apply gradual pressure to bend or fold to the desired contour.

- Smooth edges with fine sandpaper or a deburring tool.

- Clean the surface to remove filings or residue.

Each step promotes accuracy and prevents cracking. The UK metal structure manufacturing industry, which encompasses fabrication work, is a £8.4 billion sector. It employs thousands of people across 3,268 businesses, according to industry analysis.

Our material categories include cut-to-size aluminium plate, ready for bending or folding to save time and reduce waste.

Practical Tips for Accurate Results

Accuracy in metal shaping relies on patience, precision, and consistent technique. Each metal responds differently to pressure and heat, so gradual adjustments are essential. Metal fabrication best practices emphasise steady pressure and proper material alignment. These are crucial for preventing surface defects and structural weaknesses during forming operations.

To improve results:

- Practise on offcuts to understand how materials react.

- Apply controlled, even force to maintain consistency.

- Record measurements for repeatable outcomes.

- Inspect surfaces regularly for distortion or cracks.

These habits improve precision and reduce waste. Just take a look at the UK Metals Council’s industry report for 2024/2025. It shows that companies in the metal processing and fabrication sector continue to invest in quality and efficiency. They do this to stay competitive in both local and global markets. Learners using cut-to-size materials from us can focus on shaping accuracy rather than preparation.

For further guidance, visit our blog for updates on fabrication techniques and safe working practices.

Build Precision and Confidence in Metal Shaping

Learning metal shaping at home develops skill and confidence. Using an aluminium plate helps beginners see how pressure and angle affect results. This leads to clean and consistent outcomes. With accurate measurement and the right tools, small projects can reach professional quality.

Clickmetal provides precision-cut metals, ISO-accredited quality, and dependable nationwide delivery. With over 70 years of experience, the company continues to supply trusted materials and technical support across the UK.

Call 01794 526090, get in touch and start shaping with confidence today.