Aluminium is a lightweight, conductive and adaptable metal that is easy to cut, drill and weld. Its versatility is why it’s been used for a variety of domestic and commercial projects over the years. However, it’s wise to understand if aluminium tubing is best suited for your next project, especially if you’re not sure if it’s the right metal for the job.

With over 70 years’ experience within the metal industry, we feel we are best placed to explain to you everything you need to know about aluminium tubing, and how we can supply the right aluminium for your next project.

Contact us today to learn more about aluminium tubing for your project.

What is aluminium tubing?

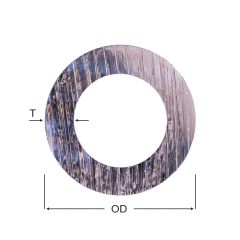

An aluminium tube is usually a hollow pipe made of pure aluminium or aluminium alloy. It can be circular, rectangular, square or elliptical and is available in different diameter sizes and wall thicknesses.

What is aluminium tubing used for?

Aluminium can be used for:

- Everyday household items and appliances

- Structures and buildings

- Planes, trains and automobiles

We have a whole blog dedicated to this topic – “What is aluminium used for?” for a deeper dive into each of these uses.

Aluminium tube grades and sizes

We provide aluminium tubes in alloy grade 6063T6 up to 16swg (1.6mm) thick and in alloy grade 6082T6 for 10swg (3.2mm) and thicker.

We recommend reading our “Choosing the right aluminium grade for your project” blog to learn more about the aluminium grades available.

How do you join aluminium tubes?

Welding

Most aluminium alloys can be welded together, typically with a gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW).

Using connectors

With the right sized aluminium tubes and the relevant connectors, aluminium can be pushed into the connector with the use of a rubber mallet for a tight, snug fit.

Brazing rod

Aluminium tubes can also be connected using a propane torch and some aluminium brazing rods. It can create a very strong bond with little practice required.

See our latest blog ‘How to join aluminium without welding’ for more ideas to join aluminium tubing.

Aluminium tubes vs steel tubes

We specialise in supplying both aluminium tubing and stainless steel tubing, and based on our expertise we understand each metal has its own strengths and weaknesses. This is also based on how the metals are produced on a spectrum of alloys, allowing for different chemical and physical properties.

We break down our comparison of the two metals into separate categories to help you determine what will be more preferable for your project.

Weight

Based on volume, steel is three times heavier than aluminium.

If you’re looking to produce kitchen supplies, medical tools or for aerospace manufacturing then we’d recommend opting for aluminium. However, if your metal is for structural purposes we suggest choosing steel as it will do the job at a lower cost.

Strength

Stainless steel’s increased weight allows for increased strength. Steel can withstand higher shock, impact and stress than aluminium and is less likely to bend under pressure.

Stainless steel has further strength capacity thanks to its alloy – high carbon steels are harder and sturdier than low carbon steels.

Durability

Stainless steel is typically more durable and less likely to scratch than aluminium.

The biggest durability concern with steel is that it is usually mixed with an iron alloy meaning it’s very prone to rusting. Aluminium, on the other hand, does not rust but can corrode – however due to an aluminium oxide coating it typically does not.

Cost

Cost is quite difficult to quantify. A pound of aluminium will cost more than a pound of steel, but as aluminium is lighter, you’ll get more material per pound.

Once produced, the costs tend to balance out, but you’ll also need to consider the cost of the type of alloy you’ll want to add to your metal.

Clickmetal are specialist aluminium tubing suppliers

We are a leading UK supplier of aluminium and other nonferrous metals. We specialise in cutting down all metal to your required size, delivering nationwide to both the trade and to customers domestically.

Choose from our wide array of aluminium and stainless steel metal options. Order online today for bespoke sizing and quick, nationwide delivery.

Get in touch today

To learn more about how we can supply the right aluminium for your next project, enquire today via our contact webpage or give us a call on 01794 526090.

Aluminium Tubing FAQs

What colour is aluminium tube metal?

Depending on the roughness of the surface, aluminium’s appearance ranges from silvery white to dull grey.

How long can aluminium tubes last?

Aluminium is especially durable, lasting for decades. The lifespan of aluminium in the construction sector is 60 years, but depending on who you talk to it can take up to a century before decomposing.

Can aluminium tubes be recycled?

Absolutely – aluminium is incredibly eco-friendly. As one of the most sustainable materials, it can be recycled forever.

Do aluminium tubes rust?

No, but do be aware that aluminium does corrode. That’s why an aluminium oxide coating is applied to the metal which is highly resistant to corrosion. Can you bend aluminium tubes? Yes – you can bend tubing of up to 1.25 inches by hand, however, a manual pipe bender or hydraulic bender will make this easier.

How much weight do aluminium tubes hold?

This will vary on:

- the size

- the thickness

- if it’s rectangular or round tubing

- if it’s solid or hollow

We can work with you to give you approximations on load bearing weight for your chosen aluminium tube. Do note stainless steel tubes typically hold more weight than aluminium ones when compared at the same size.

How can I make my aluminium tubes stronger?

With hollow aluminium tubes, we recommended filling the tube with concrete to increase the weight load without bucking the top or compression side of the tube.